Our Manufacture

1. Advanced equipment and technology

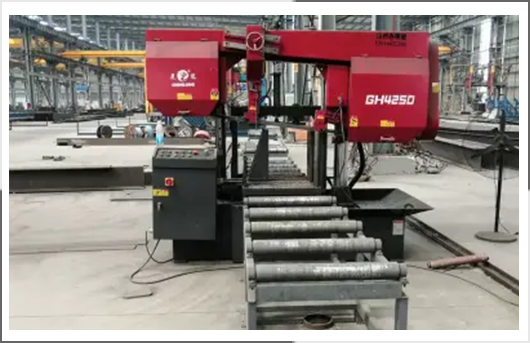

High-end processing equipment: The company is equipped with CNC cutting machines, automatic welding robots, laser cutting machines, 3D drilling machines and other modern equipment to ensure the accuracy and efficiency of component processing.

Intelligent production line: Automatic production line is used to realize the whole process automation from blanking, cutting, welding, drilling to assembly, greatly improving production efficiency and product quality.

2. Exquisite processing technology

Precision blanking and cutting: Through CNC technology to achieve high-precision cutting of steel, to ensure that the component size error is controlled at the millimeter level.

High quality welding: With a professional welding team and advanced welding technology (such as gas shielded welding, submerged arc welding, etc.), to ensure that the weld strength is high, the appearance is smooth, in line with international standards.

Complex component molding: It can deal with complex structures such as special-shaped components and curved components to meet diversified design needs.

3. Strict quality control

Whole-process quality inspection: From raw material storage to finished product delivery, each link is strictly quality inspection, including dimensional inspection, weld non-destructive testing (such as ultrasonic, X-ray testing).

Standardization process: Follow international quality management system such as ISO9001 to ensure standardization and standardization of production process.

Third party certification: Through the testing and certification of authoritative institutions, to ensure that product quality reaches the industry-leading level.

4. Efficient production capacity and delivery capacity

Large-scale production capacity: with large factories and production lines, we can handle multiple large-scale projects at the same time to meet the high requirements of customers for construction periods.

Quick response ability: Through scientific production planning and resource a

Modular production: The use of modular design and prefabrication technology to reduce site construction time and improve overall efficiency.

5. Technological innovation and R&D capability

Technology research and development team: We have a professional research and development team, committed to the development and application of new processes and new materials, and constantly improve the production level.

Application of intelligent technology: BIM (Building information model) technology is introduced to achieve seamless connection between design and production and optimize the production process.

Green manufacturing: The use of environmental protection technology and energy-saving equipment to reduce energy consumption and pollution in the production process, reflecting the concept of sustainable development.

6. Rich project experience

Diversified cases: Participated in large-scale venues, high-rise buildings, Bridges, industrial plants and other types of steel structure projects, accumulated a wealth of production experience.

Difficult projects: able to deal with large span, super high-rise, special-shaped structure and other difficult projects, showing the company's technical strength in complex structure production.

7. Professional team support

Technical team: with experienced engineers and technicians, we can provide customers with a full range of technical support from design to production.

Skilled workers: Have a skilled and experienced production team to ensure the technical level of each link.

8. Perfect after-sales service

After-sales tracking: Provide the whole process tracking service from production to installation to ensure the smooth implementation of the project.

Problem solving: Quickly respond to customer feedback, provide technical support and solutions to ensure customer satisfaction.